Nylon Family Page

Nylatron® MD Page

Nylon Family Page

Nylatron® MD Page

Size and Availability:

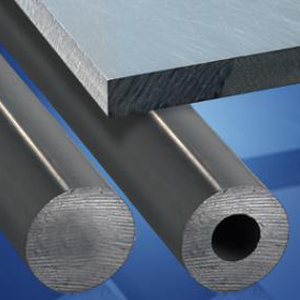

Sheet / Slab stock

- Thickness: 1/16”thk to 4”thk

- Sheet sizes: 24”x 24” and 24”x 48”

Rod / Round stock

- Diameters: 3/16”dia to 12”dia

- Rod length: 1 ft, 4 ft and 8 ft lg., varies by diameter

|

Nylon is one of the most

widely used and versatile thermoplastic resins. Its combination of physical properties

and reasonable price make it a favorite

choice for numerous applications. Nylons toughness, wear resistance, tensile strength

and lubricity make it a good choice for many mechanical machine parts.

Nylon MD is a nylon and molybdenum disulfide (MoS2) composition designed to improve

the mechanical, thermal and bearing properties to type 6/6

nylon while maintaining its basic electrical and chemical characteristics.

Through compounding, finely divided particles impart extra lubricity to this nylon,

permitting Nylon MD parts to operate with little or no lubrication. This

makes it especially suited to applications where external lubrication is impractical,

contaminating or difficult to maintain. The added lubricity also

contributes dramatically to component service life, making Nylon MD a very cost-efficient

choice.

Nylon MD provides non-galling and non-scratching characteristics, sound dampening

qualities, insulating properties, resistance to oils, greases, most alkalies,

solvents, and organic acids

Features:

- Greater wear resistance

- Lower surface friction

- Higher strength and greater rigidity

- Improved dimensional stability

Applications:

- Bearings

- Bushings

- Valve seats

- Thrust washers

- Wear surfaces

- Rollers

- Gears

- Sleeves

- Forming dies

- Tooling fixtures

Engineering Note:

Nylons can absorb up to 7% (by weight) water under high humidity or submerged in water. This can result in dimensional changes up to 2%

and a corresponding reduction of physical properties. Proper design techniques can frequently compensate for this factor.

|