Chemical Composition

Silicon: 0.4%

Iron: 0.7%

Copper: 5%-6%

Lead: 0.2%-0.6%

Bismuth: 0.2%-0.6%

Zinc: 0.3%

|

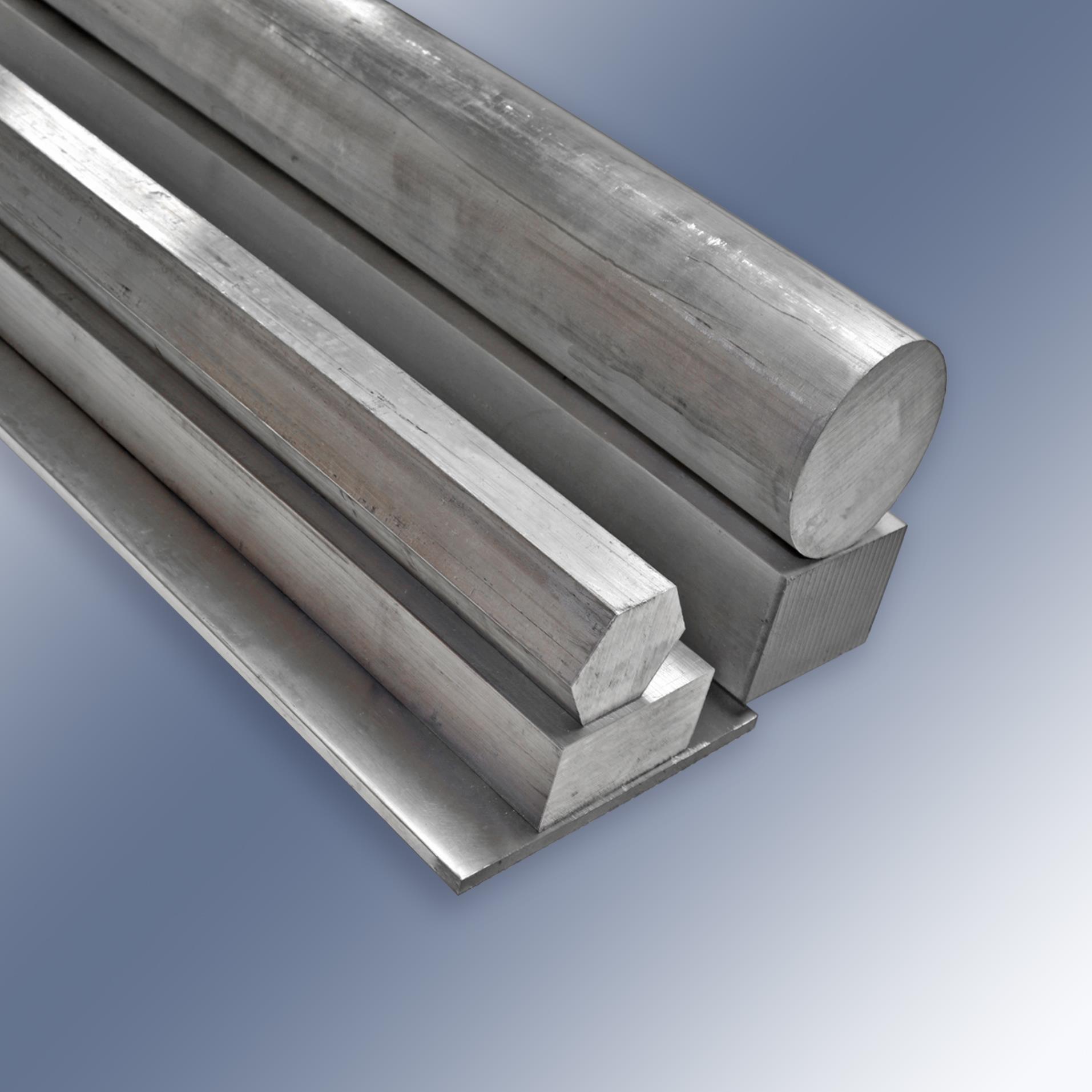

2011 Cold Finish Aluminum Bar

2011 grade aluminum bar is known for its free machining elements (lead and bismuth) 2011 machines exceptionally well. It chips break small and easily, and can be machined to close tolerances while affording smooth, bright finishes. Fine aluminum chips equates to faster feeds and longer tool life. 2011 has good strength and average formability. Electrical conductivity is 38% of copper. It can also be anodized to enhance corrosion resistance.

These characteristics make 2011 Cold Finished Aluminum Bar the most widely used of the aluminum alloys for screw machine parts.

Machining 2011 CF Bar

In terms of machinability 2011 CF aluminum compares to free cutting brass. It is the most suitable alloy for machining on automatics, milling machines, lathes, planers, shapers and other machine tools, and is the most widely used alloy for all types of screw machine parts. It can be machined at high speeds and comparatively heavy feeds. Machined surfaces are bright and smooth. Mechanical finishes readily match joined parts. Mechanical properties and hardness are excellent; corrosion resistance fair.

Weldability by resistance method is fair; other welding is not recommended.

Properties

The physical properties of 2011 greatly depend on the temper of the material. If you require certain physical properties for your application, please contact an Alro Sales Representative to make sure this material will meet your needs.

Typical Uses

Typical uses for 2011 include:

- Connectors

- fittings

- brake pistons

- computer parts

- knobs

- meter shafts

|

|