Alro Plastics offers a wide range of Industrial Grade Laminates in sheet, rod, tubing and fabricated parts made to print.

Industrial Laminates are usually made using at least two components such as a reinforcing substrate and a thermoplastic

resin binder, then cured with high temperature and pressure. The reinforcing substrate can be glass cloth, glass mat, filaments, canvas cotton fabric, linen cotton fabric,

paper, graphite fabric, and others. While the thermoplastic binder resin which serves to adhere the layers together can be epoxies, melamine, phenolics, polyesters, silicones, and others.

Alro Plastics offers a wide range of Industrial Grade Laminates in sheet, rod, tubing and fabricated parts made to print.

Industrial Laminates are usually made using at least two components such as a reinforcing substrate and a thermoplastic

resin binder, then cured with high temperature and pressure. The reinforcing substrate can be glass cloth, glass mat, filaments, canvas cotton fabric, linen cotton fabric,

paper, graphite fabric, and others. While the thermoplastic binder resin which serves to adhere the layers together can be epoxies, melamine, phenolics, polyesters, silicones, and others.

Micarta (Phenolic) is a trademark of Norplex-Micarta industrial high-pressure laminates. Common uses of modern high-pressure laminates are electrical insulators, printed circuit board substrates, and knife handles.

Industrial Laminates also have their own set of standards which are determined by NEMA (National

Electrical Manufacturers Association). NEMA standards are set and minimum values are published. Below

are some of the most commonly used NEMA thermoset laminate grades:

Electrical Grade Laminates

Electrical Grade Laminates |

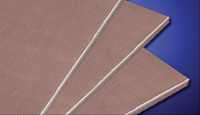

Phenolic C consists of a cotton canvas fabric and general-purpose phenolic resin. The product is

easy to machine and operates with less noise than metal. In addition, this material is not as

abrasive as fiberglass alternatives when used in wear applications.

Phenolic C consists of a cotton canvas fabric and general-purpose phenolic resin. The product is

easy to machine and operates with less noise than metal. In addition, this material is not as

abrasive as fiberglass alternatives when used in wear applications.

|

Phenolic CE (NEMA CE) consists of a cotton canvas type fabric and electrically insulating phenolic

resin system. Phenolic CE is easy to machine and operates with less noise than metal.

Phenolic CE (NEMA CE) consists of a cotton canvas type fabric and electrically insulating phenolic

resin system. Phenolic CE is easy to machine and operates with less noise than metal.

Phenolic CE Typical Properties

Phenolic CE Typical Properties

Phenolic CE MSDS

Phenolic CE MSDS |

Phenolic LE (NEMA LE) is used where better machining is needed compared to that offered by canvas

grades This product consists of a fine-weave linen fabric and electrical grade of phenolic resin.

Phenolic LE (NEMA LE) is used where better machining is needed compared to that offered by canvas

grades This product consists of a fine-weave linen fabric and electrical grade of phenolic resin.

Phenolic LE Typical Properties

Phenolic LE Typical Properties

Phenolic LE MSDS

Phenolic LE MSDS

|

Phenolic XX (NEMA XX) is a paper based phenolic that is a machining grade with less robust electrical

properties than those of Phenolic XXX. Designed for electrical insulation, the product can be used in

dry or high humidity conditions.

Phenolic XX (NEMA XX) is a paper based phenolic that is a machining grade with less robust electrical

properties than those of Phenolic XXX. Designed for electrical insulation, the product can be used in

dry or high humidity conditions.

Phenolic XX Typical Properties

Phenolic XX Typical Properties

Phenolic XX MSDS

Phenolic XX MSDS

|

A continuous glass fabric laminated with a silicone resin. Grade G-7 is unequalled for high heat and

arc resistance applications, and where good mechanical and electrical properties must be exhibited in

humid conditions in excess of 500°F.

A continuous glass fabric laminated with a silicone resin. Grade G-7 is unequalled for high heat and

arc resistance applications, and where good mechanical and electrical properties must be exhibited in

humid conditions in excess of 500°F.

|

G-9 is a continuous woven glass fabric laminated with a melamine resin. Grade G-9 has good mechanical

properties plus high resistance to flame, heat, arcing, and most strong alkali solutions. It is

recommended for use where good mechanical properties are needed under wet conditions.

G-9 is a continuous woven glass fabric laminated with a melamine resin. Grade G-9 has good mechanical

properties plus high resistance to flame, heat, arcing, and most strong alkali solutions. It is

recommended for use where good mechanical properties are needed under wet conditions.

|

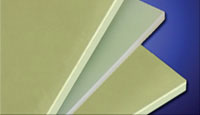

G-10 / FR4 is a continuous woven glass fabric laminated with an epoxy resin. This grade is extremely high in mechanical strength, has low water

absorption and dissipation factors and has superior electrical characteristics, which are exhibited over a wide range of temperatures and humidity.

Grade G-10 is used for terminal boards, washers, sleeves, structural components, and parts where the strength to size ratio is critical.

G-10 / FR4 is a continuous woven glass fabric laminated with an epoxy resin. This grade is extremely high in mechanical strength, has low water

absorption and dissipation factors and has superior electrical characteristics, which are exhibited over a wide range of temperatures and humidity.

Grade G-10 is used for terminal boards, washers, sleeves, structural components, and parts where the strength to size ratio is critical.

G-10 / FR4 Typical Properties

G-10 / FR4 Typical Properties

G-10 / FR4 MSDS

G-10 / FR4 MSDS

|

G-11 is a grade similar in composition and properties to Grade G-10 but more suitable for continuous use at elevated temperature. G-11

retains at least 50% of its structural strength at continuous operating temperatures in excess of 300°F. Due to its high cost, G-11 applications

are limited to only the most critical high heat situations.

G-11 is a grade similar in composition and properties to Grade G-10 but more suitable for continuous use at elevated temperature. G-11

retains at least 50% of its structural strength at continuous operating temperatures in excess of 300°F. Due to its high cost, G-11 applications

are limited to only the most critical high heat situations.

G-11 MSDS

G-11 MSDS

|

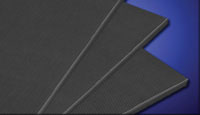

GPO-3 is an electrical grade sheet laminate produced by using polyester resin and fiberglass

reinforcement. They are U.L. recognized and are available in 36” x 72” and 48” x 96” sheets.

Track resistant, flame retardant laminate which meets or exceeds NEMA GPO-3 requirements.

GPO-3 is an electrical grade sheet laminate produced by using polyester resin and fiberglass

reinforcement. They are U.L. recognized and are available in 36” x 72” and 48” x 96” sheets.

Track resistant, flame retardant laminate which meets or exceeds NEMA GPO-3 requirements.

|

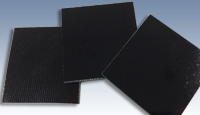

Matrix HT maintains rigidity with excellent dimensional stability and creep resistance over

wide temperature ranges, as well as good resistance to moisture, chemicals, alkali and acids. It does not melt or soften at high temperatures,

and offers users extended application capability beyond typical NEMA grades.

Matrix HT maintains rigidity with excellent dimensional stability and creep resistance over

wide temperature ranges, as well as good resistance to moisture, chemicals, alkali and acids. It does not melt or soften at high temperatures,

and offers users extended application capability beyond typical NEMA grades.

|