Colors/Grades:

Size and Availability:

Sheet / Plate:

- Thickness: 1/32�thk to 4�thk (standard increments)

- Sheet size: 24� x 48� and 48�x 120� standard

Rod / Rounds:

- Diameters: 1/8�dia to 10�dia

- Lengths: 4 ft, 5 ft, 8 ft and 10 ft, varies by diameter.

Tubing / Bushing stock:

- Diameters: 3�OD to 9-1/2�OD (wall thickness varies)

- Lengths: 8 foot standard, may vary with OD size

Hex Rod Stock:

- Hex sizes: 3/16� wide to 1� wide

- Lengths: 8 foot standard

|

Acetal plastics are ideally suited for close tolerance mechanical parts and electrical insulators, which require strength and stiffness. Acetal plastics also resist a wide range of chemicals, including many solvents. Alro Plastics offers both homopolymer and copolymer grades of acetal, including three enhanced bearing grade materials.

Acetal Plastic Properties:

As a semi-crystalline material, acetal is characterized by a low coefficient of friction and good wear properties-especially in wet environments. Because acetal absorbs minimal moisture, its physical properties remain constant in various environments. Low moisture absorption gives excellent dimensional stability for close-tolerance machined parts. In high moisture or submerged applications, acetal bearings outperform nylon 4 to 1.

Acetal Copolymer Plastic Options:

Acetal copolymer plastics are available in various formats to meet your application needs. Standard acetal copolymer plastic options include:

- Sheet

- Plate

- Rod

- Tubing

- Bushings

The Alro Advantage

Alro is a direct supplier and distributor of premium acetal copolymer plastics. Whatever your project requires, we can provide high-quality acetal plastic products to meet your specifications. Request a quote and we will help you find the products you need.

Acetal�s beneficial features include:

- Low moisture absorption

- High strength and stiffness

- Easy to machine

- Dimensionally stable for tight tolerances

- No centerline porosity

- FDA, USDA, NSF, Canada AG and 3-A Dairy compliant

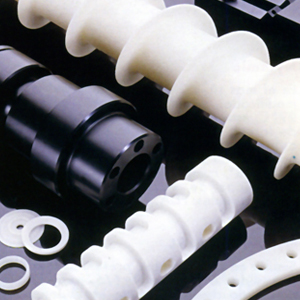

Acetal Copolymer Plastic Applications:

Acetal plastics are ideally suited for the following applications and environments:

- Bearings and bushings

- Electrical components

|

- Structural keels

- Gears and rollers

|

Engineering Note:

In general, acetals do not perform as well in abrasive wear applications as nylons. Compensation for moisture-related growth generally allows nylons to be used for wet, abrasive applications. If your application requires dimensional consistency in an abrasive, high humidity, or submerged environment, Ertalyte� PET-P will often offer improved performance.

|