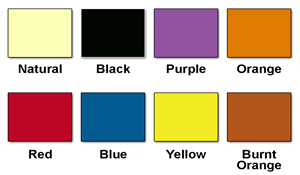

Colors/Grades:

Size and Availability:

Sheet / Plate:

- Thickness: 1/4”thk to 1”thk (in 1/8” increments)

- Thickness: 1-1/4” to 4”thk (in 1/4” increments)

- Sheet sizes: 24”x 48”, 28”x 57”, 36”x 48” and 48”x 120”

Rod / Round :

- Diameters: 1”dia to 13”dia

- Lengths: 24” and 48”long (varies by diameter)

Tubular Bar:

- Diameters: 2”OD to 40”OD (wall sections ¼” to 4”thk)

- Lengths: 13”, 26” and 39” (varies by diameter)

Discs:

- Diameters: 14”dia to 60”dia

- Thickness: Starts at 1”thick and goes up

Rings:

- Diameters: 14”OD to 60”OD

- Thickness: Starts at 2”thick and goes up

|

Nylon is one of the most widely used and versatile thermoplastic resins. Its combination of physical properties and reasonable price make it a favorite

choice for numerous applications. Nylons toughness, wear resistance, tensile strength and lubricity make it a good choice for many mechanical machine parts.

- Nylon has a consistent history of replacing other materials including: metal, brass, bronze, aluminum and rubber. In replacing metal gears in machinery,

Nylon can be advantageous because of its ability to reduce noise, use less lubrication and increase gear life. It can also be lighter weight as Nylon weighs

1/7 as much as Bronze. Nylon can also be fabricated on most mills with high precision.

Cast Nylon exhibits all the properties which generally make nylon a superior engineering material: high strength, low friction and wear resistance. However,

because of the casting process, part size and thickness are almost unlimited without degradation of the materials internal structure. Cast Nylon meets FDA

standards.

Features:

- High impact resistance

- Excellent vibration resistance

- Resistance to brittleness and deterioration

- Easy to machine and fabricate

- Good abrasion resistance

- High heat distortion temperature

Applications:

- Gears & sprockets

- Bushings & bearings

- Wear shoes & pads

- Sheaves & pulleys

- Feed screws

- Wear rails & strips

- Scraper blades

- Supports

- Housings

Engineering Note:

Nylons can absorb up to 7% (by weight) water under high humidity or submerged in water. This can result

in dimensional changes up to 2% and a corresponding reduction of physical properties. Proper design

techniques can frequently compensate for this factor.

|