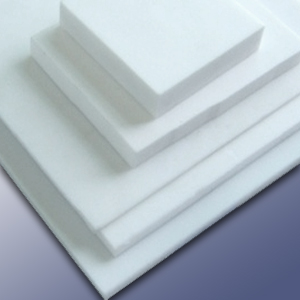

Alro Plastics offers PTFE or TFE (polytetra-fluoroethylene), a very dense material

having a density of 2.13 - 2.19 grams/cc. PTFE is well known for its chemical resistance. It is insoluble in all organics with the exception of a few exotics.

Electrical properties are excellent. Impact strength is high but its resistance to wear, tensile strength and creep resistance are low in comparison to other engineering materials.

Alro Plastics offers PTFE or TFE (polytetra-fluoroethylene), a very dense material

having a density of 2.13 - 2.19 grams/cc. PTFE is well known for its chemical resistance. It is insoluble in all organics with the exception of a few exotics.

Electrical properties are excellent. Impact strength is high but its resistance to wear, tensile strength and creep resistance are low in comparison to other engineering materials.

Mechanical properties can be improved by adding fillers such as glass fibers, bronze, carbon, and graphite. PTFE has an extremely low coefficient of friction.

Very few materials will stick to it. It has useful properties from cryogenic temperatures up to 260°C(550°F). PTFE is also offered in FDA compliant grades for food grade applications.

See below for the different grades available within the PTFE family of plastics.

|

PTFE is a fluorocarbon solid, as it is a high molecular weight compound consisting wholly of carbon and fluorine. PTFE has one of the lowest

coefficients of friciton of any solid. It is very non-reactive, partly because of the strength of carbon-fluoride bonds, and so it is often used

in containers and pipework for reactive and corrosive chemicals.

PTFE is a fluorocarbon solid, as it is a high molecular weight compound consisting wholly of carbon and fluorine. PTFE has one of the lowest

coefficients of friciton of any solid. It is very non-reactive, partly because of the strength of carbon-fluoride bonds, and so it is often used

in containers and pipework for reactive and corrosive chemicals.

|

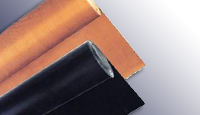

PTFE Coated Conveyor Belts are used in a variety of applications where materials are handled in a high heat environment, from screen print

dryers used in the textile industry to extruded rubber products used in the automobile industry. Belts are designed for top performance and durability

in high-heat environments.

PTFE Coated Conveyor Belts are used in a variety of applications where materials are handled in a high heat environment, from screen print

dryers used in the textile industry to extruded rubber products used in the automobile industry. Belts are designed for top performance and durability

in high-heat environments.

|

PTFE fabrics are used to manufacture an extensive line of belts and fabricated parts ranging in thickness from .003" to over .060".

Available with fiberglass, Kevlar® and Nomex® substrates, these products are fabricated in widths ranging from 1/4" up to 141"

(certain fabric styles only).

PTFE fabrics are used to manufacture an extensive line of belts and fabricated parts ranging in thickness from .003" to over .060".

Available with fiberglass, Kevlar® and Nomex® substrates, these products are fabricated in widths ranging from 1/4" up to 141"

(certain fabric styles only).

|

PTFE Tapes are self-lubricating with low coefficients of friction to help improve web processing. Chemical-resistant and temperature resistant

up to 400°F(204°C), they provide long performance on heat-sealing machines. Their anti-stick properties enable easy cleanup of hot plastic.

PTFE Tapes are self-lubricating with low coefficients of friction to help improve web processing. Chemical-resistant and temperature resistant

up to 400°F(204°C), they provide long performance on heat-sealing machines. Their anti-stick properties enable easy cleanup of hot plastic.

|

With its high lubricant performance, high melting temperature, biocompatibility, and super precision extruded tolerances, PTFE Thin Wall Tubing

is the best choice for your demanding application. It is chemically resistant to all common solvents, acids and bases, and lowest coefficient of friction of all polymers.

PTFE also has excellent dielectric insulation properties.

With its high lubricant performance, high melting temperature, biocompatibility, and super precision extruded tolerances, PTFE Thin Wall Tubing

is the best choice for your demanding application. It is chemically resistant to all common solvents, acids and bases, and lowest coefficient of friction of all polymers.

PTFE also has excellent dielectric insulation properties.

|

|