Chemical Composition

Carbon: 0.030% (Max)

Manganese: 1.00% (Max)

Silicon: 1.00% (Max)

Phosphorous: 0.040% (Max)

Sulfur: 0.020% (Max)

Chromium: 10.5%-11.7%

Nickel: 0.50%

|

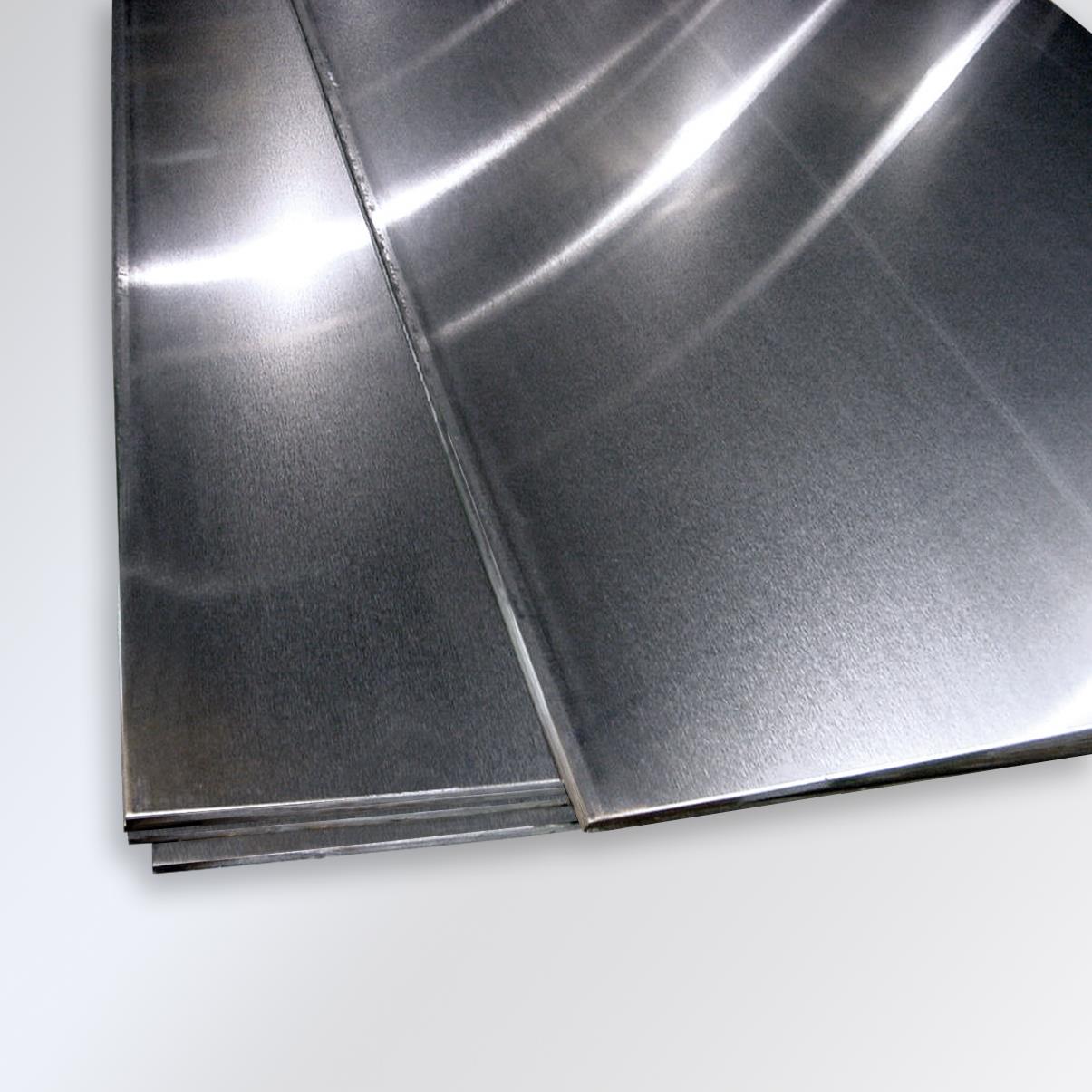

409 Stainless Steel Sheet, Pipe, Tube

Grade 409 is a stabilized ferritic general purpose stainless steel with 11% chromium. It is especially useful for applications requiring oxidation or corrosion protection beyond the capability of carbon steel and some coated steels. 409 has good oxidation resistance and formability, but lower corrosion resistance due to the chromium content. 409 is not as corrosion resistant as 304, 430 or 439 grades, however, 409 is far superior to mild carbon steel. 409 can be formed by roll forming, stretch bending, deep drawing or pressing. In the annealed condition 409 does not harden when cold worked using mild roll forming techniques including pressing or stretch-bending. Welding performance for grade 409 is fair. This stainless steel material should not be used in impact-loaded structures, because in heat affected zones the grain structure can grow which may have a direct effect on the mechanical properties. 409 is commonly used for tubing and stampings in motor vehicle exhaust system applications.

Properties

Tensile Strength: 55 ksi (380 MPa)

Yield Strength: 25 ksi (170 MPa)

Elongation: > or equal 20% in 2"

*These numbers are "Typical" properties and may not be required to meet this grade. Please check with your Alro Sales Representative if physical properties are required for your application.*

Typical Uses

- Exhaust applications

- Stamping

- Cold forming applications

|

|