|

|

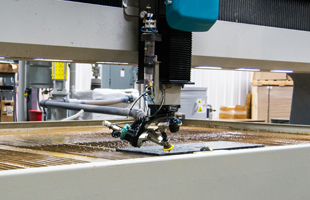

Waterjet Cutting

|

|

Waterjet Cutting is a great alternative to traditional Plate Processing. Use waterjet for cutting jigs, mechanical parts or customized tooling. Waterjet cutting eliminates the need for drilling and punching, and is perfect for cutting Stainless Steel, Aluminum, Alloys, Copper, Brass, Bronze, and even Plastics. Advantages include:

- No heat affected zones

- More accurate cutting in all materials

- Produces a near net finished part

- Thicker cutting with minimal distortion

- Reduces or eliminates secondary machining operations

- Tighter nesting for optimal material utilization

|

Alro can waterjet cut up to 8" thick pieces in a single pass, depending on material.

With a very narrow kerf line, waterjet cutting allows for tighter nesting than other methods.

With a 120" x 240" maximum plate capacity, Alro can handle almost any waterjet cut job.

|

Thickness

Capacity |

Tolerance (tightest available)

(Aluminum, Copper, Brass / SS, MS) |

Minimum Hole Size

(Aluminum, Copper, Brass / SS, MS)

|

Max Plate Capacity

|

Acceptable Materials

|

11 gauge

up to

8" thick

|

Up to 1.25" thick (.010" / .010")

1.25" to 2.50" (.010" / .040")

2.50" to 3.50" (.040" / .080")

3.50" to 5.00" (.080" / .125")

5.00" to 8.00" (.125" / .180")

|

Up to .50" dia (.200" / .250")

.50" to 1.25" (.250" / .375")

1.25" to 2.50" (.300" / .500")

2.50" to 5.00" (.375" / .625")

5.00" to 8.00" (1.000" / 1.500")

|

120" x 240"

|

Alloys • Aluminum • Carbon Steel

Plastics • Red Metals

Stainless • Tool Steel

|

|

This chart is a guideline only. For more specifc information, please contact your Alro representative. |

|

Alro has a fully integrated CAD Department to handle most file types:

Preferred Files: .dxf .dwg .iges

|

Also Accepted:

.asm .prt .dft .par .psm .pwd .step .X_B .X_T .sat model .iam .stp .ipt .dgn .sldasm .sldprt .stl

|

|

|