|

|

Press Brake Forming

|

|

With multiple machines of varying capabilities, Alro Steel is uniquely qualifed to cut and form your custom parts. Along with standard formed shapes, Alro is capable of producing more complex parts such as:

- 3- and 4-sided pans

- Multiple profile parts

- Overbending of a variety of thickness

- Multiple hit "step brake/rolled parts"

Alro continually invests in new technology and updating their machines to provide the highest quality parts.

|

Our press brakes are capable of bending up to 20 ft. long depending on material thickness.

Rolla-V Dies are perfect for bending special materials, difficult radius and min. flanges.

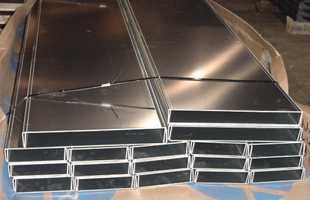

Custom stainless steel channels formed to customer specifcations

|

Maximum

Bend Length |

Materials Capabilities |

Tolerance

on Bend

|

Tolerance

on Leg

|

| Carbon |

Stainless |

Aluminum

|

Red Metals

|

Up to 20 ft.

*Depending on

material thickness

|

20 ga.

up to

5/8" thick

|

20 ga.

up to

5/8" thick

|

20 ga.

up to

5/8" thick

|

20 ga.

up to

5/8" thick

|

+/- 1 degree |

20 ga - 5/16" = 1/16" overall

3/8" - 1/2" = 1/8" overall

|

|

This chart is a guideline only. For more specifc information, please contact your Alro representative. |

|

Alro has a fully integrated CAD Department to handle most file types:

Preferred Files: .dxf .dwg .sldprt .prt

|

Also Accepted:

.iges .asm .dft .par .psm .pwd .step .X_B .X_T .sat model .iam .stp .ipt .dgn .sldasm .stl

|

|