Chemical Composition

Carbon (C) .65/.75

Manganese (Mn) .25/.80

Silicon (Si) .50 max

Molybdenum (Mo) .50 max

Chromium (Cr) .60/1.20

Vanadium (V) .30 max

*Nickel (Ni) 1.25/2.00

*Unless otherwise specified, nickel plus copper equal 0.75% max. for all tool steel types

|

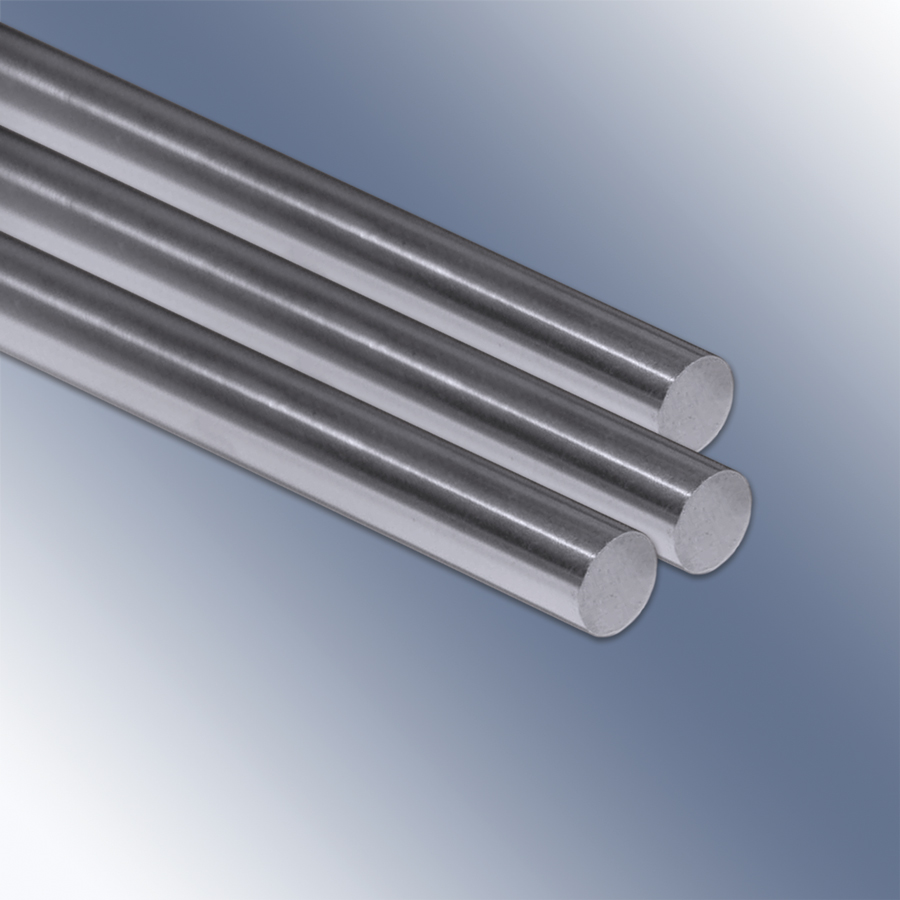

Oil Hardening AISI L6 Tool Steel

AISI L6 tool steel possesses a fine-grained structure and is noted for it's shock resistance. Compared to other oil-hardened steels, L6 is a tough steel that possesses high strength and good non-deforming characteristics. This is due to the high nickel content in this alloy steel.

Alro stocks L6 in Round Bars, however other shapes are available through Alro Steel upon request. Contact us for a quote today.

More About L6 Tool Steel

L-6 steel has a long history of being used to make knives and swords. It is particularly prized for the hardness which allows knives from L6 to hold their edge and wear extremely well. L6 is weldable, and can be formed using conventional methods.

Properties

L-6 is typically bought to meet chemistry requirements rather than physical requirements. For that reason, physical properties are generally not provided unless requested prior to production. Any material can be sent to a third party after production to be tested for physical properties.

Typical Uses

Typical Applications for L-6 Tool Steel include:

- Coining Dies

- Forming Rolls

- Knives

- Spindles

- Punches

- Trim Dies

- Blanking Dies

- Embossing Dies

- Forming Dies

- Shear Blades

|

|