Ultra-high-molecular-weight polyethylene (UHMWPE or sometimes shortened to UHMW),

also known as high-modulus polyethylene (HMPE) or

high-performance polyethylene (HPPE), is a subset of the thermoplastic polyethylene.

It has extremely long chains, with molecular weight

numbering in the millions, usually between 2 and 6 million. The longer chain serves

to transfer load more effectively to the polymer

backbone by strengthening intermolecular interactions. This results in a very tough

material, with the highest impact strength of any

thermoplastic presently made. It is highly resistant to corrosive chemicals, with exception

of oxidizing acids. It has

extremely low moisture absorption, has a very low coefficient of friction, is self-lubricating,

and is highly resistant to abrasion (15

times more resistant to abrasion than carbon steel). Its coefficient of friction is

significantly lower than that of acetal. It is odorless, tasteless, and nontoxic.

Ultra-high-molecular-weight polyethylene (UHMWPE or sometimes shortened to UHMW),

also known as high-modulus polyethylene (HMPE) or

high-performance polyethylene (HPPE), is a subset of the thermoplastic polyethylene.

It has extremely long chains, with molecular weight

numbering in the millions, usually between 2 and 6 million. The longer chain serves

to transfer load more effectively to the polymer

backbone by strengthening intermolecular interactions. This results in a very tough

material, with the highest impact strength of any

thermoplastic presently made. It is highly resistant to corrosive chemicals, with exception

of oxidizing acids. It has

extremely low moisture absorption, has a very low coefficient of friction, is self-lubricating,

and is highly resistant to abrasion (15

times more resistant to abrasion than carbon steel). Its coefficient of friction is

significantly lower than that of acetal. It is odorless, tasteless, and nontoxic.

|

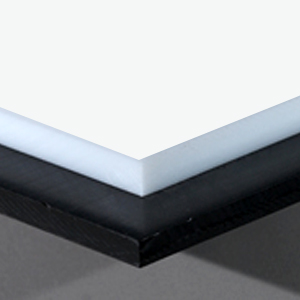

TIVAR®1000 UHMW is an excellent general purpose wear material that meets FDA, USDA,

& 3-A Dairy guidelines for pharmaceutical processing and food

contact applications. Standard colors are Natural (White) and Black, custom colors are

also available.

TIVAR®1000 UHMW is an excellent general purpose wear material that meets FDA, USDA,

& 3-A Dairy guidelines for pharmaceutical processing and food

contact applications. Standard colors are Natural (White) and Black, custom colors are

also available.

|

Blue in color, is recognized worldwide as the premium lining material for bulk material

handling, TIVAR® 88 is noted for its

performance in promoting bulk solids flow of cohesive or non-free flowing materials

due to its low surface friction.

Blue in color, is recognized worldwide as the premium lining material for bulk material

handling, TIVAR® 88 is noted for its

performance in promoting bulk solids flow of cohesive or non-free flowing materials

due to its low surface friction.

|

TIVAR® CeramP is a shatter resistant alternative to ceramics. TIVAR® CeramP is noted

for dimensional stability. TIVAR® CeramP is a proven

performer in high speed, high load

TIVAR® CeramP is a shatter resistant alternative to ceramics. TIVAR® CeramP is noted

for dimensional stability. TIVAR® CeramP is a proven

performer in high speed, high load

|

TIVAR®

CleanStat is a static-reduced product that meets FDA & USDA guidelines for food

handling and pharmaceutical processing. TIVAR®

CleanStat is weldable and will eliminate static build-up problems while exhibiting a

longer-wearing, lower-coefficient of friction

sliding surface than stainless steel. TIVAR®

CleanStat is a static-reduced product that meets FDA & USDA guidelines for food

handling and pharmaceutical processing. TIVAR®

CleanStat is weldable and will eliminate static build-up problems while exhibiting a

longer-wearing, lower-coefficient of friction

sliding surface than stainless steel.

|

TIVAR®

DockGuard provides dock fender facing that outlasts other materials such as wood,

rubber, urethane or high density polyethylene.

The ideal material for marine fender systems, TIVAR® DockGuard allows vessels to glide

easily along its surface without marring hulls. TIVAR®

DockGuard provides dock fender facing that outlasts other materials such as wood,

rubber, urethane or high density polyethylene.

The ideal material for marine fender systems, TIVAR® DockGuard allows vessels to glide

easily along its surface without marring hulls.

|

TIVAR®

DrySlide is modified with special dry additives for enhanced coefficient of friction

and antistatic properties. TIVAR® DrySlide

is effective in dusty environments where components need extra lubrication and anti-static

properties. TIVAR®

DrySlide is modified with special dry additives for enhanced coefficient of friction

and antistatic properties. TIVAR® DrySlide

is effective in dusty environments where components need extra lubrication and anti-static

properties.

|

TIVAR®

ESD is an ideal material to use when potentially volatile conditions exist, such

as those in grain elevators and munitions plants,

effectively safeguarding against static discharges. TIVAR®

ESD is an ideal material to use when potentially volatile conditions exist, such

as those in grain elevators and munitions plants,

effectively safeguarding against static discharges.

|

TIVAR®

H.O.T. is formulated to maintain key performance properties in an extended temperature

range, TIVAR® H.O.T. will excel in

a variety of industrial manufacturing environments where temperatures range up to 275°F. TIVAR®

H.O.T. is formulated to maintain key performance properties in an extended temperature

range, TIVAR® H.O.T. will excel in

a variety of industrial manufacturing environments where temperatures range up to 275°F.

|

TIVAR® HPV was developed specifically for wear components subject to challenging

production environments, such as high speeds,

high temperatures, high loads and aggressive cleaning agents. TIVAR® HPV is also FDA

compliant.

TIVAR® HPV was developed specifically for wear components subject to challenging

production environments, such as high speeds,

high temperatures, high loads and aggressive cleaning agents. TIVAR® HPV is also FDA

compliant.

|

TIVAR®

MD

has been specifically tailored for use in the food processing and packaging industries

where it can easily be traced by the conventional metal detection systems installed

to

detect contamination of the foodstuffs (results may vary depending on the sensitivity

of

the metal detection system used). TIVAR®

MD

has been specifically tailored for use in the food processing and packaging industries

where it can easily be traced by the conventional metal detection systems installed

to

detect contamination of the foodstuffs (results may vary depending on the sensitivity

of

the metal detection system used).

|

TIVAR®

Oil Filled is an enhanced dynamic coefficient of friction formula, exuding an oil

additive to lubricate mating surfaces.

This is commonly used for applications requiring higher pressure velocity values. TIVAR

Oil Filled meets FDA & USDA guidelines

for food contact applications. TIVAR®

Oil Filled is an enhanced dynamic coefficient of friction formula, exuding an oil

additive to lubricate mating surfaces.

This is commonly used for applications requiring higher pressure velocity values. TIVAR

Oil Filled meets FDA & USDA guidelines

for food contact applications.

|

TIVAR®

PolySteel is compounded to achieve specific gravity >1 (won't float); activates

metal detectors. TIVAR® PolySteel has

been specially formulated to create a magnetically detectable polymer material that

can be separated from wood pulp in solution. TIVAR®

PolySteel is compounded to achieve specific gravity >1 (won't float); activates

metal detectors. TIVAR® PolySteel has

been specially formulated to create a magnetically detectable polymer material that

can be separated from wood pulp in solution.

|

TIVAR®

U.V. Resistant is modified for enhanced stability in outdoor applications and is

available black as a

standard and also in custom colors. Outdoor applications for TIVAR® U.V. Resistant are

endless. TIVAR®

U.V. Resistant is modified for enhanced stability in outdoor applications and is

available black as a

standard and also in custom colors. Outdoor applications for TIVAR® U.V. Resistant are

endless.

|

TIVAR® VMX Food Grade UHMW-PE is an EU 10/2011 and FDA 21 CFR § 177.1520 compliant material containing a metal detectable additive. The material has been specifically tailored for use in the food processing and packaging industries where it can easily be traced by different detection systems installed to detect contamination of the foodstuffs. TIVAR® VMX Food Grade presents excellent toughness and impact strength and even improved wear and abrasion resistance compared with TIVAR® 1000 and therefore makes this grade especially suited for wear and friction applications.

|