Nylatron®

Nylon is one of the most widely used and versatile

thermoplastic resins. Its combination of physical properties and reasonable price make it a favorite choice for numerous applications. Nylons

toughness, wear resistance, tensile strength and lubricity make it a good choice for many mechanical machine parts. Nylon is also lightweight,

weighing only 1/7 the weight of Bronze. Nylon is one of the most widely used and versatile

thermoplastic resins. Its combination of physical properties and reasonable price make it a favorite choice for numerous applications. Nylons

toughness, wear resistance, tensile strength and lubricity make it a good choice for many mechanical machine parts. Nylon is also lightweight,

weighing only 1/7 the weight of Bronze.

Nylatron® is a registered trade name of Quadrant EPP. The Nylatron® product line

features a variety of materials designed to excel in specific applications. Please read below on each specific Nylatron® product for more

information.

|

Nylatron® GS (extruded nylon) is a molybdenum disulphide (MoS2) filled

nylon offering improved strength and rigidity. With a lower coefficient of linear thermal expansion than Nylon 101, Nylatron® GS parts maintain

better fit and clearances, and have less tendency to seize as bearings. Nylatron® GS (extruded nylon) is a molybdenum disulphide (MoS2) filled

nylon offering improved strength and rigidity. With a lower coefficient of linear thermal expansion than Nylon 101, Nylatron® GS parts maintain

better fit and clearances, and have less tendency to seize as bearings.

Nylatron® GS Typical Properties Nylatron® GS Typical Properties

Nylatron® GS MSDS Nylatron® GS MSDS

|

Nylatron® GSM (cast nylon) contains finely divided particles of molybdenum

disulphide (MoS2) to enhance its load bearing capabilities while maintaining the impact resistance inherent to nylon. Nylatron® GSM (cast nylon) contains finely divided particles of molybdenum

disulphide (MoS2) to enhance its load bearing capabilities while maintaining the impact resistance inherent to nylon.

Nylatron® GSM Typical Properties Nylatron® GSM Typical Properties

Nylatron® GSM MSDS Nylatron® GSM MSDS

|

Nylatron® GSM Blue is the first cast nylon to combine both molybdenum

disulphide (MoS) and oil for the load capacity of Nylatron® GSM nylon, plus improved frictional characteristics. It excels in higher pressures,

and at low speeds-up to 40 fpm. Nylatron® GSM Blue is the first cast nylon to combine both molybdenum

disulphide (MoS) and oil for the load capacity of Nylatron® GSM nylon, plus improved frictional characteristics. It excels in higher pressures,

and at low speeds-up to 40 fpm.

Nylatron® GSM Blue Typical Properties Nylatron® GSM Blue Typical Properties

Nylatron® GSM Blue MSDS Nylatron® GSM Blue MSDS

|

Nylatron® LIG combines the toughness of cast PA6 with an oil-based lubricant

that is encapsulated within the nylon matrix. Nylatron® LIG increases the load bearing performance of the material when compared to unfilled nylons and

reduces the coefficient of friction. Nylatron® LIG combines the toughness of cast PA6 with an oil-based lubricant

that is encapsulated within the nylon matrix. Nylatron® LIG increases the load bearing performance of the material when compared to unfilled nylons and

reduces the coefficient of friction.

Nylatron® LIG Typical Properties Nylatron® LIG Typical Properties

Nylatron® LIG MSDS Nylatron® LIG MSDS

|

Nylatron® LFG takes the performance of Nylatron® LIG and adds FDA compliance

for applications where food contact is possible. Food packaging and processing equipment users can now benefit from the benefits of this material. Nylatron® LFG takes the performance of Nylatron® LIG and adds FDA compliance

for applications where food contact is possible. Food packaging and processing equipment users can now benefit from the benefits of this material.

Nylatron® LFG Typical Properties Nylatron® LFG Typical Properties

Nylatron® LFG MSDS Nylatron® LFG MSDS

|

Nylatron® NSM outperforms all other "premium" wear grade materials by far.

Ideal for bearings and wear pads, Nylatron® NSM offers advantages beyond superior wear resistance at an affordable price. It provides weight and

noise reduction, corrosion resistance, and easy machining. Nylatron® NSM outperforms all other "premium" wear grade materials by far.

Ideal for bearings and wear pads, Nylatron® NSM offers advantages beyond superior wear resistance at an affordable price. It provides weight and

noise reduction, corrosion resistance, and easy machining.

Nylatron® NSM Typical Properties Nylatron® NSM Typical Properties

Nylatron® NSM MSDS Nylatron® NSM MSDS

|

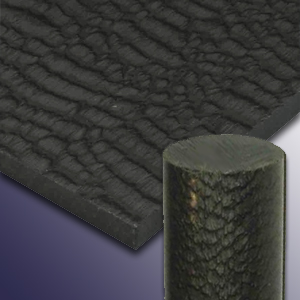

Developed specifically for wear pads, Nylatron WP outperforms its competition across a wide range of applications and in multiple industries. Nylatron WP offers an economical solution to provide superior performance, weight and noise reduction, corrosion resistance, and easy machining. Developed specifically for wear pads, Nylatron WP outperforms its competition across a wide range of applications and in multiple industries. Nylatron WP offers an economical solution to provide superior performance, weight and noise reduction, corrosion resistance, and easy machining.

Nylatron® WP Typical Properties Nylatron® WP Typical Properties

Nylatron® WP MSDS Nylatron® WP MSDS

|